VCANUS Universal Robot Transformation - X

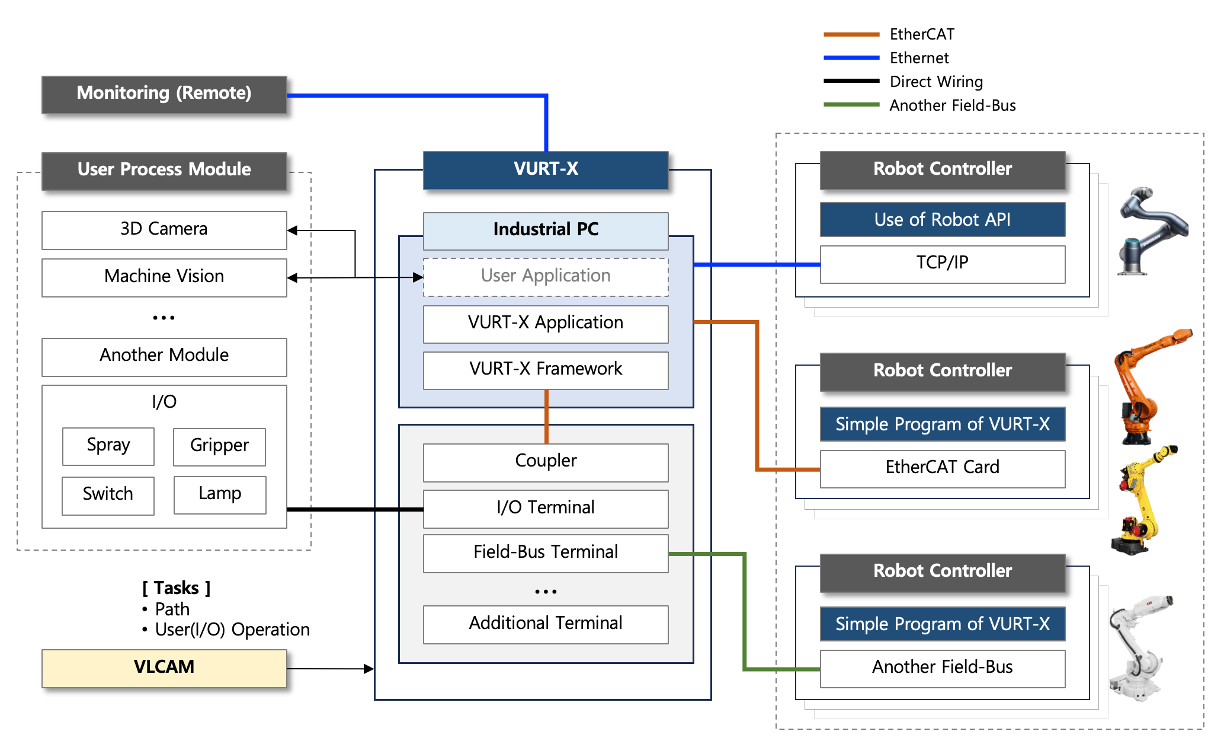

VURT-X is a universal robot transformation platform designed for virtual simulation and direct real-time control of industrial and collaborative robots. By replacing manual teaching processes and eliminating traditional robot code, VURT-X enables faster deployment, greater flexibility, and simplified automation through intuitive sequence management and direct GUI-based operation. VURT-X provides a unified platform to manage multiple robot brands—such as KUKA, Stäubli, FANUC, ABB, and Rainbow Robotics—through a single, common interface, removing the need for brand-specific programming. Additionally, VURT-X integrates Beckhoff PLC functionality, enabling seamless I/O signal control (e.g., lamps, switches, buttons) essential for automation systems. For manufacturers managing diverse robot fleets, VURT-X reduces setup time, minimizes programming complexity, and enhances operational efficiency, making robot deployment and management more systematic and cost-effective.

Why Is a Universal Robot Transformation Needed?

Traditional robot programming relies on teach pendants and manual coding, which are time-consuming, error-prone, and inflexible. This approach not only delays deployment but also increases maintenance efforts, especially when managing multiple robots. VURT-X solves these challenges by:

- Eliminating manual teaching through direct GUI-based control.

- Removing traditional robot code with automated sequence management.

- Enabling virtual simulation for path verification and collision detection.

- Providing real-time monitoring and 3D visualization for precise operation and diagnostics. By replacing fragmented, brand-dependent workflows with a unified and scalable solution, VURT-X accelerates deployment, reduces engineering overhead, and improves productivity.

What You Can Do with VURT-X

With VURT-X, users can:

- Simulate and verify motion paths and detect collisions in a virtual environment.

- Operate robots directly via an intuitive GUI, without teach pendants.

- Synchronize robot and external system movements for coordinated, high-precision tasks.

- Monitor robot status in real time with 3D visualization.

- Create, simulate, and execute sequences—including point-to-point motion and custom tasks (e.g., pick-and-place, inspection, packaging, labeling).

- Program and utilize an embedded PLC for advanced automation logic.

Key Features

Robot Compatibility

- Industrial Robots: KUKA, Stäubli, FANUC, ABB, etc.

- Collaborative Robots: Rainbow Robotics, Doosan Robotics, Neuromeka

Virtual Simulation

- User-defined 3D model management (tools, targets, obstacles).

- Motion feasibility verification and collision detection.

- Sequence simulation and validation.

Direct Operation

- Manual/Auto operation modes.

- Jogging, rapid traverse, linear, and joint motion.

- Point-to-point and joint-angle motion control.

Real-time Control & Synchronized Motion

- Data exchange with external systems (EtherCAT, TCP/IP, Beckhoff ADS).

- Cycle time: 4–10 ms (varies by robot and protocol).

- Velocity and position synchronization for multi-axis coordination.

Real-time Monitoring & 3D Visualization

- Live monitoring of robot status (joint angles, positions, etc.).

- Real-time PLC value tracking.

Sequence Control & Task Management

- Sequence control (start, stop, pause, reset).

- Task creation, registration, and management (point-to-point motion, PC or PLC-linked custom tasks).

- Interlock setting for safe task execution.

High Extensibility

- Automatic path/sequence generation via CAM software integration.

- Compatibility with measurement devices (3D vision, ToF cameras, stereo cameras, etc.).

PLC Programming & Utilization

- Supported languages: LD (Ladder Diagram), FBD (Function Block Diagram), ST (Structured Text), SFC (Sequential Function Chart), C/C++.

- Read/write PLC parameters for seamless automation logic integration.

Error Management

- Error compensation (setup error: coordinate compensation; position error: 3D table-based compensation).

- Error table management (registration, updates).

Centralized Control of Robot Systems (Enterprise Edition)

- Integration of multi-brand robots via a common interface and user-friendly GUI.

- Real-time sequence control for multiple robots, eliminating the need for individual pendants.

- Integrated monitoring of the entire shop floor with 3D visualization.