VCANUS Intelligent Manufacturing Solutions

Smart Vision. Precise Control. Seamless Automation.

VCANUS delivers end-to-end Intelligent Manufacturing Solutions by integrating TSLoom, VURT-X, VRCAM, Edge AI, and 3D Measurement technologies. Our expertise spans machine vision, robotic automation, and AI-driven process optimization, enabling manufacturers to achieve real-time monitoring, predictive control, and autonomous production. With proven experience in roll-to-roll coating, display defect classification, machine alignment, metal 3D printing, and laser-based material processing, we empower industries to enhance quality, reduce waste, and optimize efficiency through intelligent automation.

Why VCANUS Intelligent Manufacturing?

VCANUS enables manufacturers to:

- Automate complex processes using machine vision, Edge AI, and robotic systems.

- Monitor and control quality in real time with adaptive feedback.

- Optimize production workflows through AI-driven analytics and process simulation.

- Integrate seamlessly with MES, ERP, and PLC systems for closed-loop automation.

- Deploy scalable solutions tailored to specific industry needs.

Our solutions combine cutting-edge technology with deep domain expertise, delivering actionable insights and tangible ROI for smart factories.

Core Technologies & Solutions

1. Machine Vision-Based Intelligent Manufacturing

Leverage TSLoom and Edge AI to transform visual data into actionable intelligence:

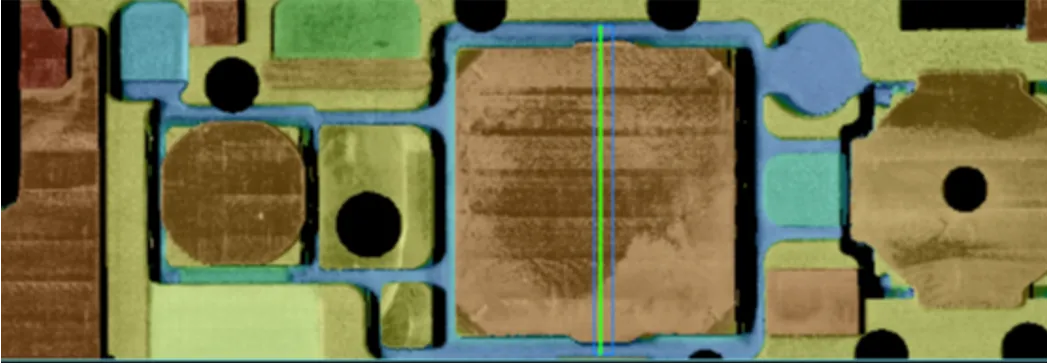

Roll-to-Roll Coating System

- Meniscus Shape Detection: Use machine vision to detect meniscus shape characteristics.

- Coating Thickness Prediction: Apply AI models to predict coating thickness in real time.

- Process Optimization: Dynamically adjust coating parameters to ensure uniformity.

Display Defect Classification

- Defect Detection: Identify micro-defects in display panels using high-resolution cameras.

- Classification & Analysis: Classify defects by type, size, and location with machine learning.

- Root Cause Analysis: Correlate defects with process parameters to pinpoint issues.

Machine Alignment

- Edge & Polygon Detection: Use pattern matching and geometric alignment to set machine origins.

- Automated Calibration: Achieve micrometer-level precision in machine setup.

Metal 3D Printing System

- Melting Pool Monitoring: Capture IR camera images of the melting pool.

- Adaptive Laser Control: Adjust laser power in real time to maintain consistent melting pool size.

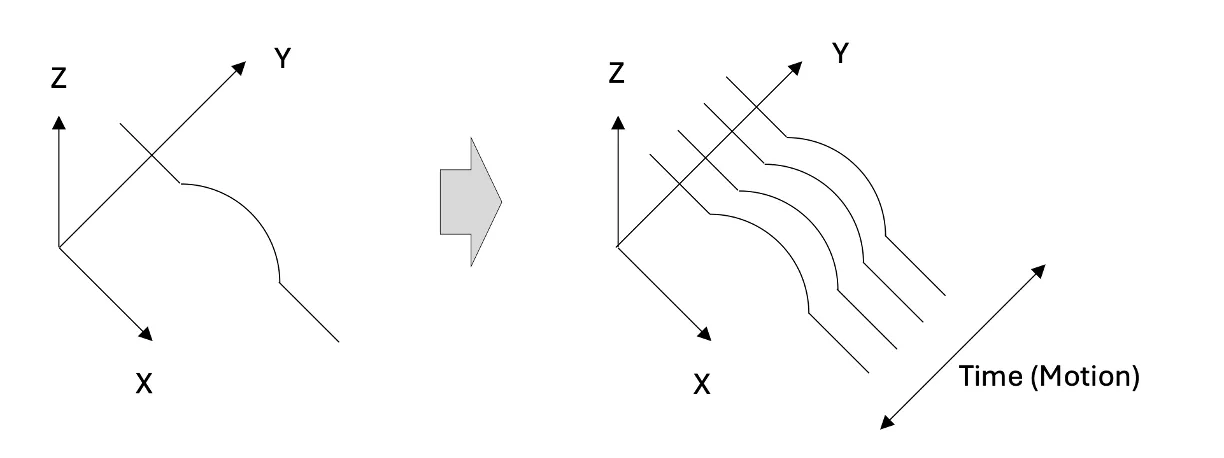

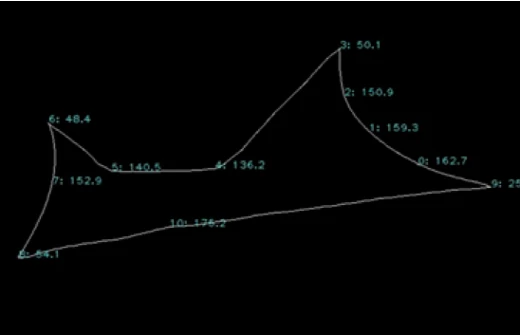

2. Distance Displacement Sensor-Based Manufacturing

Utilize 1D/2D displacement sensors for inline inspection and 3D profiling:

Inline Part Inspection

- 1D/2D Sensor Integration: Deploy sensors for real-time dimensional checks.

- Defect Detection: Identify surface defects, warpage, and dimensional deviations.

3D Shape Measurement

- 2D Sensor + Actuator Systems: Combine sensors with linear actuators to create 3D profiles of complex parts.

- Automated Reporting: Generate pass/fail reports based on tolerance limits.

|

|

|---|---|

| Real-Time Dimensional Inspection | 3D Profiling with Linear Actuators |

3. Advanced Robotic Applications

Innovate with VRCAM and VURT-X for precision material processing:

Laser-Based Material Removal System

- 3D Scanning & Path Planning: Use VRCAM to map part surfaces and generate optimal tool paths.

- Adaptive Material Removal: Control robot-mounted lasers with VURT-X real-time control to remove material with micron-level precision.

Laser Sintering-Based Patterning System

- Laser Sintering Process: Create electronic circuit paths using laser sintering.

- Defect Inspection: Detect circuit defects with machine vision and AI-based analysis.

Key Benefits of VCANUS Solutions

| Solution Area | Key Benefits |

|---|---|

| Machine Vision | Real-time monitoring, defect classification, and adaptive process control. |

| Distance Displacement Sensors | High-speed inline inspection, 3D profiling, and automated quality control. |

| Robotic Automation | Precision material processing, VRCAM path planning, and VURT-X real-time control. |

| Edge AI & 3D Measurement | Predictive analytics, statistical process control, and closed-loop quality management. |

Success Stories

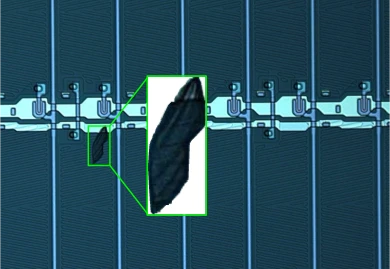

Roll-to-Roll Coating System

- Challenge: Inconsistent coating thickness due to process variations, reflected in meniscus shape changes.

- Solution: Deployed machine vision + AI models to predict and adjust coating parameters based on real-time meniscus analysis.

- Result: Achieved 98% accuracy in coating thickness prediction

|

|

|

|---|---|---|

| Raw Image | Meniscus Shape Detection | Feature Extraction |

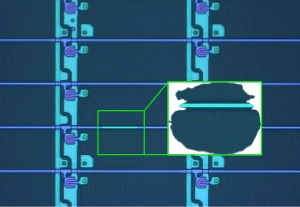

Display Defect Classification

- Challenge: Increase accuracy of defect classification.

- Solution: Enhanced defect detection performance by adding segmentation functionality and optimizing learning networks.

- Result: Achieved 5% improvement in defect detection and classification accuracy.

|

|

|

|---|---|---|

Metal 3D Printing System

- Challenge: Unstable melting pool size led to part defects.

- Solution: Used IR camera monitoring + adaptive laser control.

- Result: Achieved 20% improvement in part quality with real-time adjustments.

Laser-Based Material Removal

- Challenge: Manual material removal was inconsistent and time-consuming.

- Solution: Deployed robot-mounted laser scanners + VRCAM path planning + VURT-X real-time control.

- Result: Reduced cycle time by 20% and improved surface finish quality by 15%.

Why Choose VCANUS?

✅ Proven Expertise: Successful deployments in automotive, aerospace, electronics, and heavy industries.

✅ End-to-End Solutions: From sensor integration to AI analytics and robotic automation.

✅ Seamless Integration: Compatible with PLCs, MES, ERP, and third-party software.

✅ Scalable & Customizable: Solutions tailored to your unique production needs.

✅ Future-Ready: Continuous updates with latest AI, vision, and robotic technologies.

Industries We Serve

| Industry | Application |

|---|---|

| Automotive | Body panel inspection, coating thickness control, and robotic material removal. |

| Aerospace | Turbine blade inspection, composite material processing, and precision alignment. |

| Electronics | Display defect classification, PCB inspection, and laser sintering for circuits. |

| Heavy Machinery | Large-part 3D measurement, wear analysis, and automated welding inspection. |

| Metal 3D Printing | Melting pool monitoring, adaptive laser control, and defect detection. |

Get Started with VCANUS Intelligent Manufacturing

Transform your production with smart, data-driven solutions:

- Discuss a pilot project tailored to your needs.

- Schedule a demo of our machine vision, robotic, or Edge AI solutions.

- Explore custom solutions for your unique manufacturing challenges.