VCANUS 3D Measurement Solutions for Smart Manufacturing

Custom Robotic Scanning. Data-Driven Insights.

VCANUS delivers cutting-edge 3D measurement solutions by integrating Zeiss ATOS optical scanners with robotic automation and VURT-X for fully automated, high-efficiency dimensional analysis. Our solutions combine Zeiss’s industry-leading 3D scanning technology with VCANUS’s robotic expertise and advanced software, enabling manufacturers to capture precise 3D data, analyze dimensional variations, and make data-driven decisions for process optimization. With customizable robotic setups and AI-powered analytics, we empower you to digitize complex geometries, automate workflows, and gain actionable insights—enhancing quality, efficiency, and productivity in your production environment.

Why VCANUS 3D Measurement?

VCANUS enables manufacturers to:

- Digitize complex part geometries using Zeiss ATOS scanners mounted on industrial robots or cobots.

- Automate measurement workflows with VURT-X, reducing cycle times and eliminating manual intervention.

- Analyze measurement data with statistical tools and AI models to identify trends, correlations, and process deviations.

- Apply production-specific tolerances to automatically classify parts based on predefined control limits.

- Seamlessly integrate with MES, ERP, and CAD systems for closed-loop quality management.

Our solutions are designed for flexibility, precision, and intelligence, delivering real-time insights that drive continuous improvement.

Zeiss ATOS5 Scanners: Versatile scanner for industrial demands

VCANUS offers the full range of Zeiss ATOS scanners, trusted tools for high-resolution 3D digitization:

|

|

|

|

|

|---|---|---|---|---|

| ATOS 5 | ATOS 5 for Airfoil | ATOS 5X | ATOS LRX | |

| Your system for | High-speed 3D scanning system | Precise Scanning of smallest details | Automated scanning for large volumes | 3D scanning for very large volumes |

| Light source | LED | LED | LASER | LASER |

| Measuring points per scan | 8 or 12m | 12m | 12m | 12m |

| Working distance | 880 mm | 530 mm | 880 mm | 1810 mm |

Key Advantages of Zeiss ATOS

✅ High-resolution 3D data for detailed part analysis.

✅ Blue light and laser technology for stable measurements in industrial environments.

✅ Fast data acquisition (millions of points per second).

✅ Compatibility with GOM Inspect, PolyWorks, and VCANUS analytics software.

VCANUS Custom Robotic Measurement Solutions

1. Robot-Mounted 3D Scanning

1) Flexible Automation:

- Mount ATOS scanners on 6-axis robots or cobots for adaptive scanning of complex parts.

- Custom fixturing ensures repeatable positioning and full coverage of part surfaces. 2) VURT-X Integration:

- Automated path planning for optimal scan coverage.

- Collision avoidance and adaptive scanning for varying part geometries.

Use Cases:

- Automotive: Body panels, chassis components, and assembly verification.

- Aerospace: Airfoils, structural components, and tooling validation.

- Energy: Turbine blades, impellers, and large fabricated parts.

2. AI & Statistical Analysis Software

VCANUS provides advanced software tools to transform raw 3D data into actionable insights:

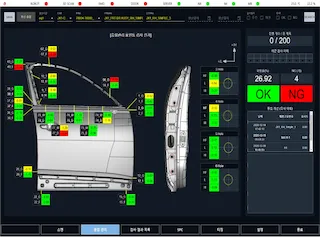

1) Tolerance-Based Classification:

- Apply production-specific tolerances to automatically classify parts as within/outside control limits.

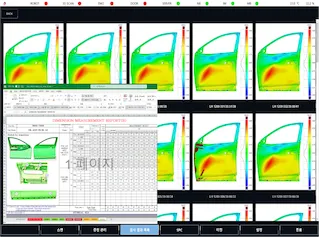

- Generate pass/fail reports based on positional tolerances (e.g., GD&T). 2) Statistical Process Control (SPC):

- Track dimensional variations over time to detect trends, shifts, or drifts.

- Correlate measurement data with process parameters (e.g., temperature, pressure) to identify root causes. 3) AI-Powered Anomaly Detection:

- Use machine learning models to detect unexpected patterns in measurement data.

- Predict potential issues before they affect production quality.

Example Workflow (Automotive Mass Production):

- Scan: Robot-mounted ATOS captures 3D data of a car body panel.

- Align: Software aligns scan data to CAD nominals.

- Analyze:

- Compare measurements against management tolerances (e.g., ±0.2 mm for critical features).

- Apply statistical models to assess process stability.

- Report:

- Automated reports highlight areas exceeding tolerances.

- Dashboards visualize trends and deviations for process engineers.

- Act:

- Adjust production parameters (e.g., fixture settings, machining paths) based on data.

3. Turnkey Robotic Measurement Cells

- ScanCell Solutions: Pre-engineered robotic cells with ATOS scanners, VURT-X, and safety systems for plug-and-play deployment.

- Inline Measurement: Integrate 3D scanning into production lines for real-time dimensional analysis.

- Portable Systems: Mobile scanning setups for large or immovable parts (e.g., vehicle frames, ship hulls).

Success Stories

Automotive Mass Production:

- 100% digital measurement of body panels in a high-volume production line.

- Error classification using position-specific tolerances, reducing manual judgment errors.

- Process optimization through measurement data-based root cause analysis, enabling targeted corrections and improved yield.

|

|

|

|

|---|---|---|---|

Why Choose VCANUS?

✅ Custom Solutions: No limitations—design systems for your unique parts and processes.

✅ Automation Expertise: VURT-X integration for unmanned, 24/7 operation.

✅ Data-Driven Insights: AI and SPC tools turn raw data into actionable improvements.

✅ Seamless Integration: Works with CAD, MES, and ERP systems.

✅ End-to-End Support: From system design to deployment and analytics.

Industries We Serve

| Industry | Application |

|---|---|

| Automotive | Body panels, chassis, assembly verification. |

| Aerospace | Airfoils, structural components, tooling. |

| Energy | Turbine blades, impellers, large fabrications. |

| Heavy Machinery | Castings, weldments, fabricated structures. |

Get Started with VCANUS 3D Measurement

Transform your manufacturing with custom 3D measurement and data intelligence:

- Discuss a pilot project tailored to your parts and processes.

- Inquire about Zeiss ATOS products.

- Schedule a demo of ATOS solutions.

- Explore our AI-powered analytics software for your measurement data.